ALL Products

-

Optical coatingOptical coatings are deposited as thin-films of a variety of materials.

Optical coatingOptical coatings are deposited as thin-films of a variety of materials.

DETAILOptical coating -

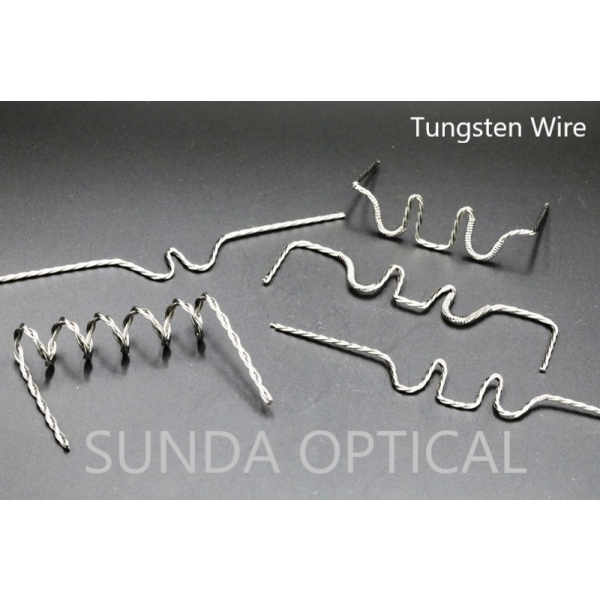

Tungsten coilsTungsten filaments in a variety of shapes and numbers of wires.DETAILTungsten coils

Tungsten coilsTungsten filaments in a variety of shapes and numbers of wires.DETAILTungsten coils -

Transparent conductive filmIt is the key material that have been widely used in industries in recent years.DETAILTransparent conductive film

Transparent conductive filmIt is the key material that have been widely used in industries in recent years.DETAILTransparent conductive film -

Evaporation material-Ti3O5The common types are granules and tablets.DETAILEvaporation material-Ti3O5

Evaporation material-Ti3O5The common types are granules and tablets.DETAILEvaporation material-Ti3O5 -

Evaporation material-ZrO2The common types are granules and tablets.DETAILEvaporation material-ZrO2

Evaporation material-ZrO2The common types are granules and tablets.DETAILEvaporation material-ZrO2 -

Evaporation material-Ta2O5The common types are granules and target.DETAILEvaporation material-Ta2O5

Evaporation material-Ta2O5The common types are granules and target.DETAILEvaporation material-Ta2O5 -

Evaporation material-SiO2、SiO2 ringThe common types are granules and tablets.DETAILEvaporation material-SiO2、SiO2 ring

Evaporation material-SiO2、SiO2 ringThe common types are granules and tablets.DETAILEvaporation material-SiO2、SiO2 ring