Aluminum is one of the most common metals in the world. It is a silvery-white, metallic material. It is light, malleable, ductile, and non-magnetic under normal conditions. Although it is not a strong material, it is a good conductor of heat and electricity and is able to form an oxide layer that is resistant to corrosion. When evaporated in a vacuum, aluminum layers form a reflective coating found on telescopes, automotive headlamps, mirrors, packages, and toys. It is widely used in the aerospace, automotive lighting, OLED, and optical industries.

Flash evaporation of aluminum is a common method of depositing large amounts of aluminum, especially in the automotive lighting and decorative industries. Pieces of aluminum (wire, canes, coils, etc.) are inserted onto tungsten filaments. The filaments are connected to electrical feedthroughs and, when sufficient current is applied, the aluminum instantaneously (flash) evaporates. There are generally many filaments connected in a deposition system, allowing for a large number of substrates to be coated simultaneously. It should be noted that not all 100% of the aluminum evaporates. A portion "wets" the tungsten and over several runs, the filament will break and need to be replaced.

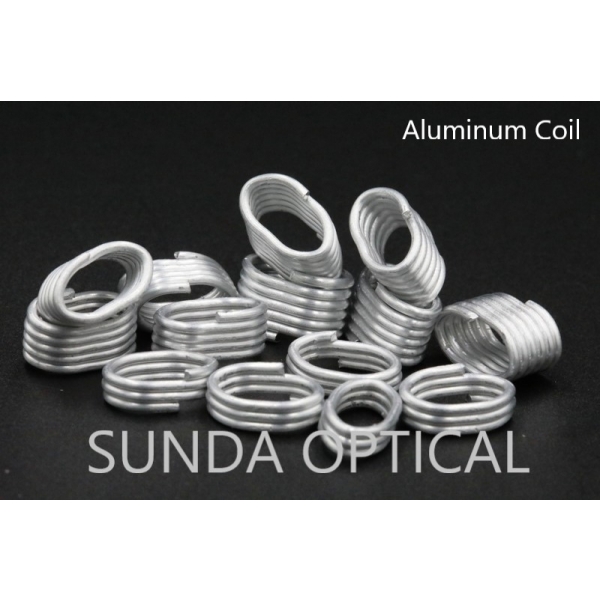

Sunda Optical can provide different specifications of aluminum coil according to your needs, and can even assist in customization.

|

Specifications |

|

|

|

|

|

3. Customized |